They are the load-carrying ball joints and therefore wear down the fastest. The ball joints are designed to help maintain the position of your vehicle against the road as the suspension moves up and down.

Some vehicles have four ball joints two connecting each front wheel.

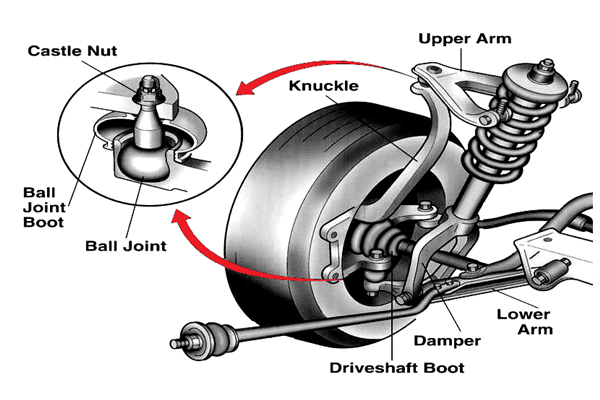

What is a lower ball joint on a car. The lower ball joint is what attaches the steering knuckle and control arm together. There are two pieces which make up the lower ball joint. A socket and ball.

These pieces are inside of a rubber boot that is filled with lubricant. Basically the lower ball joint allows the wheels and tires to be connected to the vehicle and its steering assembly. Ball joints are one of the vital parts of a vehicles suspension.

They help to keep your vehicle driving smoothly without excessive bumping or difficulty steering. In order to function your car needs to be able to navigate regularly occurring bumps in the road as well as upward and downward slopes and curves. The lower ball joint is the load-carrying joint in this type of suspension while the upper ball joint is the follower with no significant load to support.

It acts only as a second pivot point for steering. Most modern ball joints are sealed and do not require lubrication as they are lubed for life. Ball joints are an important suspension component found on virtually all modern vehicles.

They are a spherical bearing in a socket functioning similarly to the ball and socket design of a human hip and serve as one of the main suspension pivot points connecting the control arms of the vehicle to the steering knuckles. The low ball joints are usually bigger and wear out faster due to the front weight of the vehicle that rests on them. What You Should Know About Car Control Arms.

A ball joint is a round hardened steel ball with a tapered stud extruding from it. Its encased into a lubricated metal housing. Some vehicles have upper and lower ball joints.

Depending on the type of suspension some only use lower ball joints. The ball joints are designed to help maintain the position of your vehicle against the road as the suspension moves up and down. One ball joint exists on the farthest section of the lower and upper controls arms.

Also the ball joint also connects the car controls arms to the steering on either part of the vehicle. Ball joints are designed to keep your vehicles tires flat against the road as the suspension travels up and down. One ball joint is placed on the farthest edge of both the upper and lower control arms.

The ball joint connects the control arms to the steering knuckles on either side of the vehicle. Ball joints do go bad over time and must be replaced. Otherwise there may be safety issues.

Two ball joints are found on each wheel one as the upper ball joint and the other as the lower ball joint. On the other hand if your car is strut-equipped then it usually has two lower joints found in the front suspension. Types of Ball Joints.

There are two types of ball joints namely loaded ball joints and follower ball joints. A loaded ball joint means that it carries weight. The lower ball joint usually has this additional weight.

Depending on the type of suspension most cars have both upper and lower ball joints. The lower ball joints are usually larger and wear out faster due to the weight of the front of car that rests on them. Click here to read our detailed article on ball joints.

How to check ball joints and ball joint noise. Learn how to diagnose a bad ball joint for both an upper and lower control arm. I also quickly show you how to.

On some newer design multi-link independent suspensions there are two upper and two lower ball joints per corner though this style is generally only replaceable with the whole control arms. A ball joint is just what it sounds like a stud with a ball-end thats trapped in a socket so it can rotate and pivot and move relatively freely. Comments 114 A pivotal part of a vehicles suspension system a ball joint has a round ball-like head that swivels inside a cup-like socket.

Usually there are four ball joints in a cars front suspension with an upper and lower one on each wheel. Some vehicles have four ball joints two connecting each front wheel. In most cases when there is an upper ball joint and a lower ball joint but the weight of the vehicle lies entirely on the lower joint fitted with a spring.

They are the load-carrying ball joints and therefore wear down the fastest. In non-MacPherson strut automobile suspension the two ball joints are called the upper ball joint and lower ball joint. Lower ball joints are sometimes larger and may wear out faster because the fore and aft loads primarily due to braking are higher at the bottom ball joint.

When a collar of the grease fitting is flush with or below the bottom of the ball joint housing the ball joint is worn and should be replaced. Other types have a wear indicator pin protruding through a hole in the bottom of the ball joint. As long as the pin is visible the ball joint is OK.

The ACDelco Advantage Front Lower Suspension Ball Joint Assembly is designed to fit a range of GM and non-GM vehicles. The one-piece housing and polyurethane boot give the assembly strength and durability making it an economical replacement part for your vehicle. A worn-out ball joint will pivot horizontally and vertically negatively affecting your handling at low speed and becoming especially dangerous at high speeds.

Recognizable for a knocking sound in the wheel well as you execute a turn fixing old ball joints is an important part of keeping your vehicle road-safe. A ball joint links the steering knuckles and the control arms. Depending on the suspension a car can have upper and lower joints only lower joints or even rear joints.

The most common reasons for ball joint failure include wear and tear contaminants loss and lack of grease and corrosion.