These can be generally classified by looking at the position. Car differential of a Skoda 422.

Torque sensitivity HLSD Speed sensitivity.

Types of differential gears. Types of Differential and How They Work Open Differential. A differential in its most basic form comprises two halves of an axle with a gear on each end. The locked or locking differential is a variant found on some vehicles primarily those that go.

The Different Types of Gears Spur Gear. Spur gears transmit power through shafts that are parallel. The teeth of the spur gears are parallel to the.

Helical gears have teeth that are oriented at an angle to the shaft unlike spur gears which are parallel. Hypoid gears are typically found within the differential rear axle of automobiles. The gear arrangement allows the translation of torque ninety degrees.

Hypoid gears are similar to spiral bevel gears except that the shaft center lines do not intersect. There are many different types of gears aimed at a different kind of utilization scope and all types are characterized by the position of their connected axis or shaft which can be parallel intersecting or non-canonical and the shape of their teeth. Here is a list of the most common types and what they are typically used for.

An open differential OD is the most common type. It is also the least expensive. An open differential allows the vehicle to go around corners without dragging the outside wheel.

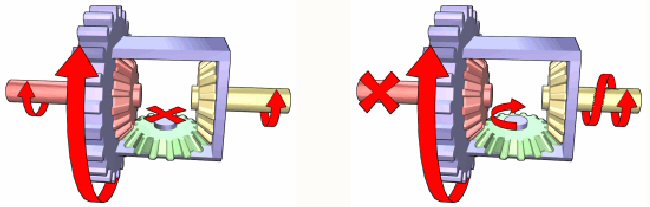

However power is transferred to the wheel with the least amount of traction grip on the road. Differential Operation Contd When turning a corner. The wheels must travel at different speeds to prevent tire scrubbing Differential pinion gears walk around slower side gear and cause other side gear to turn faster The percentage of speed that is removed from one wheel is given to the other.

There are three types of differential. A Conventional type b Non-slip or self-locking type and c Double reduction type. This section does not cite any sources.

Please help improve this section by adding citations to reliable sources. Unsourced material may. Torque sensitivity HLSD Speed sensitivity.

2 Design of a differential gear. 21 1st step drive of the separated shafts by pins and a freely rotatable bar. 22 2nd step drive of the shafts by several pins and freely rotatable bars.

23 3rd step Replacing pins and bars with bevel gears. 24 4th step drive of the shafts by further bevel gears. There are several types of bevel gears available differentiated mainly by their tooth design.

Some of the more common types of bevel gears include straight spiral and Zerol bevel gears. The drive gear 2 is mounted on the carrier 5 which supports the planetary bevel gears 4 which engage the driven bevel gears 3 attached to the axles 1. The drive shaft enters from the front and the driven axles run left and right.

Car differential of a Skoda 422. In general there are two designs of differential gears Hypoid and spiral that are used in automobiles. This was produced on a budget but its purpose is to explain the concepts and not be a Pixar-bu.

Types of GearThere are many types of gears such as spur gears helical gears worm gears etc. These can be generally classified by looking at the position. You may have heard terms like rear axle ratio or final drive ratio.

These refer to the gear ratio in the differential. If the final drive ratio is 410 then the ring gear has 410 times as many teeth as the input pinion gear. See How Gears Work for more information on gear ratios.

Three other gears like first speed second speed and reverse speed gear are also rigidly fixed to the countershaft or also known as layshaft. Two gears mounted on the splined main shaft which can be slided by the shifter yoke when the shaft lever is operated. The gears are connected to the corresponding gears of the countershaft.

1 Spur Gear-Parallel and co-planer shafts connected by gears are called spur gears. The arrangement is called spur gearing. Spur gears have straight teeth and are parallel to the axis of the wheel.

Spur gears are the most common type of gears. The primary purpose of the differential is to allow the wheels to rotate at different speeds. Differentials take the power sent from the engine and translates it from the driveshaft and via specially oriented gears into rotational motion at the wheels.

Furthermore it allows each driven wheel to turn at different speeds which is necessary for a corner.