Move a ferromagnetic. Since the damaged coil firstly the resistance is influenced.

To measure the spinning resistance of the crankshaft sensor use an ohmmeter multimeter.

Testing crank position sensor. Then using the meter red lead back probe the black ground wire at the harness connector or CKP sensor. Ask an assistant to crank the engine for a few seconds. Your DMM should register about 200mv to 300mv.

Now touch your DMM red lead to the green signal wire on the harness connector or CKP sensor. Crank the engine for a few seconds. Of course not everyone has access to a scan tool although they can sometimes be rented from parts stores but there are a few ways you can test a bad crankshaft position sensor with one.

A multimeter is a more common tool and a very useful one for diagnosing many electronic components in your vehicle. A multimeter can measure voltage current and resistance. You can remove the sensor and then test the resistance.

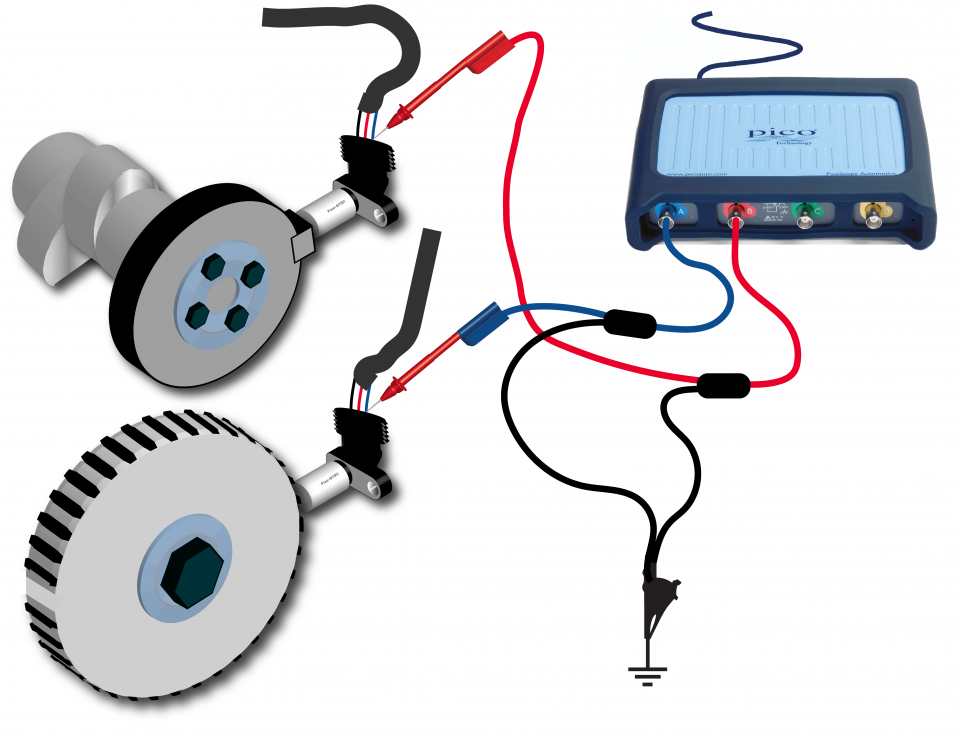

To test if it your crankshaft position sensor is working properly you have to test the voltage output. Once that is done you can compare the readings with manufacturer specifications. Step 2 - Wiring the Voltmeter.

If the voltmeter is equipped with needle probes the wires at the sensor connector need to be back probed. Step 3 - Set the Multimeter. Here is how you can easily test both your crankshaft position sensor and camshaft position sensor.

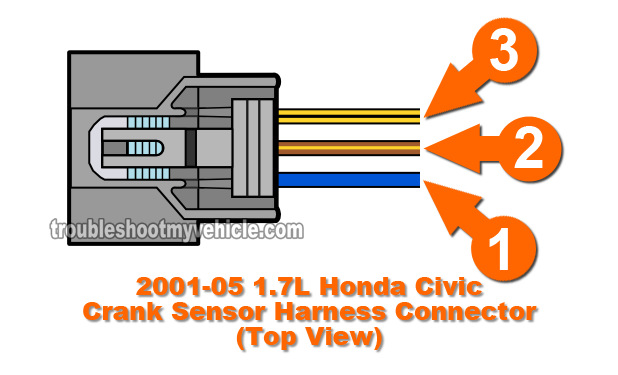

Its very important to be able to test these sensor since. Testing A Three-Wire Sensor Now come to the three wire signal crankshaft position sensor test if this is what you have. Identify three of the wires.

This time take the multi meter and set DC volts there. Similarly turn the ignition key on without turning on the. You get the black probe that.

To test two-prong crankshaft position sensors. Remove the sensor from the engine. Make sure the engine has cooled first or I dunno youll burn yourself and maybe.

Hook it up to a voltage sensor or multimeter. You only need a simple one. This simple Fluke multimeter is.

Move a ferromagnetic. To measure the spinning resistance of the crankshaft sensor use an ohmmeter multimeter. Properly functioning sensor will range from 550 to 750 ohms.

Such tester multimeter verification is the resistance testing of the coil inductive sensor. Since the damaged coil firstly the resistance is influenced. How to test a crankshaft position sensor.

Start and stall condition Cranking non-start condition Hard to start Hesitation Rough idle Poor acceleration Misfires Increased fuel consumption Check engine light on. The crank sensor test Im gonna show you in this article is one of the most accurate ways to test the crank sensor without an oscilloscope and using only a multimeter only if you turn the engine by hand. Youll need to use a 12 ratchet wrench and the appropriate socket to turn the crankshaft pulley.

Testing The CKP Signal With A Multimeter The crankshaft position sensor is located on the bottom passenger-side of the engine timing chain cover. The very first thing youll need to do is to verify if the crank sensor is producing a crank signal. This is a very easy but accurate test that will verify the performance of the CKP sensor.

Crankshaft Camshaft Position Sensor Testing Done The Easy Way April 7 2020 Engine Testing Ignition System This is a sample for 2 and 3 wire sensor When a Crankshaft Camshaft Position Sensor goes BAD your vehicle will not start. You can remove the sensor and then test the resistance. Attach one end of the multimeter to each wiring lead of the sensor.

Another way to test the crankshaft sensor with a multimeter is by checking the output voltage with the engine cranking. In this manner what happens when crank sensor is bad. If your service manual gives a resistance value you can test the sensor without having to crank up the engine.

Unplug the sensor and connect the meter probes to each sensor wire connector. Set your meter to Ohms and compare your reading to the resistance value specified in your service manual. Testing some pull down type sensors.

Connect the black multimeter test lead using the appropriate tool to the wire that connects to terminal 2 of the crank sensor harness connector. Connect the red multimeter test lead to the positive battery terminal. Your multimeter should read 10 to 12 Volts DC.

Lets take a look at what your test results mean. When the crankshaft position CKP sensor fails on your 52L V8 equipped Dakota or Durango itll cause a no start condition. In this tutorial Ill explain how to test the crankshaft position sensor on your 1997 1998 1999 52L V8 Dodge Dakota and 1998 1999 52L V8 Dodge Durango.

The test can be done with a simple multimeter and since this is an on-car test you dont have to remove it from your Dakota Durango to test it. Check the crankshaft sensor for an out-of-range or irregular signal by connecting the computer scanner to the electrical plug on the sensor. Place the scanner in the right mode by inserting the year make and engine size into the computer.

Rotate the knob down to Crankshaft sensor. Using the signal from the crankshaft sensor the ECM knows which cylinder is ready for fuel intake and then later for ignition. The crankshaft position sensor is located near below the starter motor mounted in the engine block crankcase.

The sensor reads a toothed reluctor wheel mounted to the end of the crankshaft.