Since the damaged coil firstly the resistance is influenced. So you will be avoiding a lot of problems and failures in the future.

Distributorless ignition systems DIS require a crankshaft position sensor CKP and sometimes also a camshaft position sensor CMP.

Testing crank angle sensor. Then using the meter red lead back probe the black ground wire at the harness connector or CKP sensor. Ask an assistant to crank the engine for a few seconds. Your DMM should register about 200mv to 300mv.

Now touch your DMM red lead to the green signal wire on the harness connector or CKP sensor. Crank the engine for a few seconds. Here is how to test a crankshaft position sensor with or without a code.

CKP Trouble Codes If your check engine light is on then your engine control unit ECU has recorded some sort of trouble code. You can check onboard diagnostic trouble codes with a diagnostic scan tool. Codes between P0335 and P0338 correspond to crankshaft sensor problems.

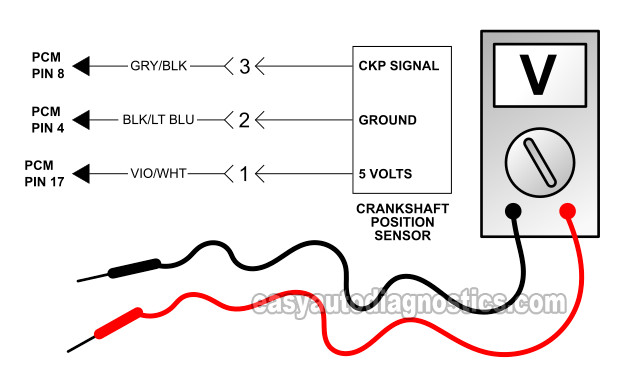

To test if it your crankshaft position sensor is working properly you have to test the voltage output. Once that is done you can compare the readings with manufacturer specifications. Step 2 - Wiring the Voltmeter.

If the voltmeter is equipped with needle probes the wires at the sensor connector need to be back probed. Step 3 - Set the Multimeter. How To Test Crankshaft And Camshaft Position Sensors.

Testing A Two-Wire SensorIn the two wire system the magnetic type you need to do the resistance test first. Testing A Three-Wire Sensor. As you may notice using a multimeter to test the crankshaft sensors performance is important.

A malfunction of this component could result in a whole cascade of problems for your vehicle. So you will be avoiding a lot of problems and failures in the future. To measure the spinning resistance of the crankshaft sensor use an ohmmeter multimeter.

Properly functioning sensor will range from 550 to 750 ohms. Such tester multimeter verification is the resistance testing of the coil inductive sensor. Since the damaged coil firstly the resistance is influenced.

When a Crankshaft Camshaft Position Sensor goes BAD your vehicle will not start. You may be inclined the take your car have the best auto repair Chantilly offers but if you like fixing up cars then you can fix this at home. Distributorless ignition systems DIS require a crankshaft position sensor CKP and sometimes also a camshaft position sensor CMP.

The crank sensor test Im gonna show you in this article is one of the most accurate ways to test the crank sensor without an oscilloscope and using only a multimeter only if you turn the engine by hand. Youll need to use a 12 ratchet wrench and the appropriate socket to turn the crankshaft pulley. Testing a crankshaft position sensor with three prongs is the same conceptually but you have to apply a voltage and ground and then test between the signal terminal and the earth.

Look at the sensor itself. Are there markings on it indicating which are the positive negative and signal terminals. The crank sensor on your 46L or 54L Ford pick up SUV or car is a two wire type crank sensor that you can easily and accurately test with a multimeter in Volts AC mode.

You dont need a scan tool to test the Ford 46L 54L crankshaft position sensor although a scan tool is a must have tool now-a-days. How Does The Crank Angle Sensor Work. Making Sure The Crank Angle Sensor Is Getting Power.

Making Sure The Crank Angle Sensor Is Getting Ground. Testing The 180 REF Signal. Testing The 1 POS Signal.

More 24L Nissan Pickup Tutorials. The crankshaft position sensor is an engine management component found on virtually all modern vehicles with internal combustion engines. It monitors the position and rotational speed of the crankshaft and sends the information to the engine control unit so it can make appropriate adjustments based on operating conditions.

If your service manual gives a resistance value you can test the sensor without having to crank up the engine. Unplug the sensor and connect the meter probes to each sensor wire connector. Set your meter to Ohms and compare your reading to the resistance value specified in your service manual.

This test result tells you that the crank angle sensor is not producing the 1 POS signal. You can conclude that the crank angle sensor is bad if you have confirmed that. The ignition coil does not spark.

The crank angle sensor is getting 10 to 12 Volts. The crank angle sensor has Ground. The crank angle sensor is creating a 180 REF signal.

How to test crankshaft position sensor for Mazda. Never seen this sensor so two ways if two wires on sensor then connect these to a multimeter and test for continuety if ok then set multimeter to lowest voltage milliamps and rapidly pass a spanner in front of the sensor backwards and forewards and see if you generate a slight voltage if one wire then use the bolt hole as the earth or ground.