These premium trimetal parts are priced higher than the aluminum alloy parts but offer the added. Assault Racing Products 81102 Small Block Chevy Engine Cam Bearing Installation Tool.

The 1 cam bearing lines up with the oil hole in the block.

Sbc cam bearing installation. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators. Check out this camshaft bearings install. It is easy to mess up cam bearings here is how its done with proper cam bearing tools.

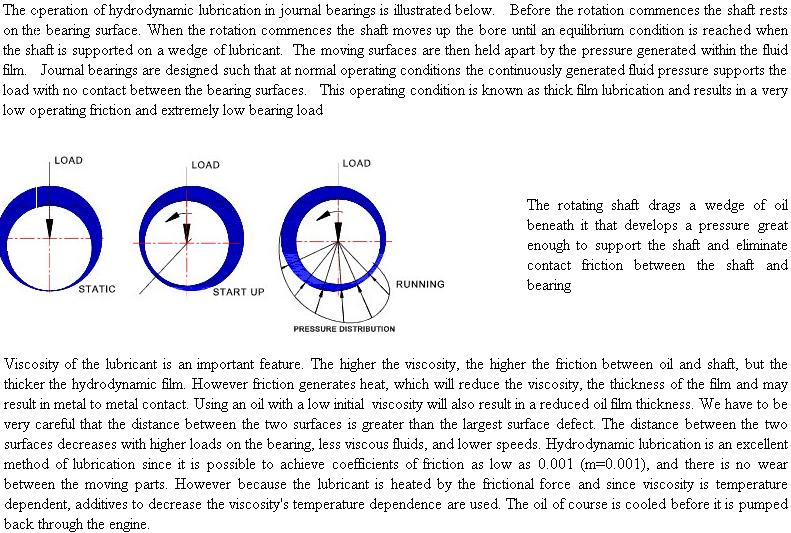

Before attempting to install the cam bearings make sure that the leading edge of each bearing bore features a slight chamfer 25-30 degrees to ease bearing installation. Where the block has a groove behind the bearing the bearing should be installed with the oil hole at the 2 oclock position when viewed from the front for normal clockwise camshaft rotation. This will introduce oil into the clearance space outside of the loaded area and allow shaft rotation to build an oil film ahead of the load.

Installation of cam bearings into the block must be done carefully to avoid shaving material from the outside diameter of the bearings. This can easily cause a buildup of excess material between the bearing and the blocks bearing bore which will squeeze the bearing resulting in oil clearance reduction at the bearing inside diameter. Just wanted to know how everyone positions the cam bearing holes in a sbc.

This is how I have been installing them. With block upright facing the front 1 1 oclock and 4 oclock 2 4 oclock 3 4 oclock 4 4 oclock 5 1 oclock. Hydrodynamic wedge is selected.

Locating and installing the cam bearing to take advantage of this hydrodynamic wedge will supply the maximum support for the camshaft during engine operation. The direction of camshaft rotation and the engine oil entry point into the bearing control the placement of the hydrodynamic wedge. A third special cam bearing set also available for the small block Chevy is the SH-1528S.

These are special trimetal bearings with 010 oversize OD for blocks align bored to 2. These premium trimetal parts are priced higher than the aluminum alloy parts but offer the added. The cam bearings in engines are removed and installed when doing a complete engine rebuild.

Begin by stripping down the engine. Once all parts are removed the cam bearings can be taken out this will help to remove any dust or dried grease that may be caught behind the bearings. Next ensure the motor is clean and prepared for assembly.

This item Camshaft Cam Bearing Driver Installation Tool Small Block Chevy ICT Billet Camshaft. Hold on to the camshaft gear and insert the opposite end into the front of the engine until the camshaft sits within the three cam bearings. Wrap the camshaft gear with a timing chain that is wrapped around the crankshaft gear.

Place the crankshaft gear over the end of the crankshaft and tap into place with a mallet. I have a 70-72 350 block. 2-4 the cam bearing holes line up with the main saddle holes.

The 1 cam bearing lines up with the oil hole in the block. In the picture shows the present position of my 5 cam bearing and DOESENT line up with any hole. Threre is a hole in the gally that goes to the bearing but is blocked by the back of the bearing.

Assault Racing Products 81102 Small Block Chevy Engine Cam Bearing Installation Tool. 43 out of 5 stars 12. Labwork Universal Engine Camshaft Cam Bearing Installation Insert Removal Remove Tool.

50 out of 5 stars 1. Camshaft Bearing Installation and Removal Tools The right tool can make any job easier and for the press-fit bearings your camshaft rides on the right tool is a camshaft bearing installer. Sometimes called a bearing knocker these tools let you tap the bearings into or out of the bores with your favorite hammer.

Cam Bearing Roller Bearing Conversion. This provides the added installation advantage of being able to install rear cam bearings from the rear of the block. IF YOU INSTALL ROLLER CAM BEARINGS.

Oil transfer grooves such as found in the number one cam bore in a smallblock Chevy must be restored following the boring operation in order to. Remove the cam sprocket so that the timing chain can be installed making sure that the timing marks on both the cam and crank sprockets align at their nearest point. Tighten the cam sprocket bolts to the proper torque value.

Insert the lifters into the lifter bores. Reinstall the push rods and pre-load the valve lash according to the cam manufacturers instructions. Blocks and heads using a 360 oil groove located behind the bearing oil feed allow one to move the clock position of the cam bearing oil feed hole.

This way you can adjust the clock position during cam bearing installation to make sure that the optimum location for the best hydrodynamic wedge is selected.