Remove the Bad Belt. Pull the fuse or trip the circuit breaker supplying electrical power to the attic fan.

If you find your fan belt is no longer attached to your engine or is lying on the ground somewhere that is definitely a sign that its time to replace your fan belt.

Replacing a fan belt. You will see YouTube videos of people replacing fan belts by prying them off the pulleys then prying the new ones on or by bumping the starter to turn the engine. Dont do that as it bends the pulleys which are made of thin cheap metal stampings for V-belts. After a while if the belt lets the water pump slide enough times the engine will overheat.

Your serpentine belt is impersonating a snake in the grass. If you find your fan belt is no longer attached to your engine or is lying on the ground somewhere that is definitely a sign that its time to replace your fan belt. Remove the Bad Belt.

If the belt is still in place but damaged so it doesnt turn the pulley properly youll need to cut it or loosen the pulleys to remove it. There are usually two bolts holding the alternator in place. Explains steps required for customer to replace Vari-Cool Fan Drive belt.

How to Change the Fan Belt on an Attic Fan Step 1. Pull the fuse or trip the circuit breaker supplying electrical power to the attic fan. If the attic fan has a.

Remove the screws surrounding the grille on the back side of the attic fan with a Phillips screwdriver. Pull one end of. The cost of fan belt will depend on the type and where its purchased from.

Serpentine belts for example can range anywhere from 8 to 50. V-belts can cost around 8 to 30 but some can cost more than 50. Toothed fan belts can cost anywhere from 6 to 20.

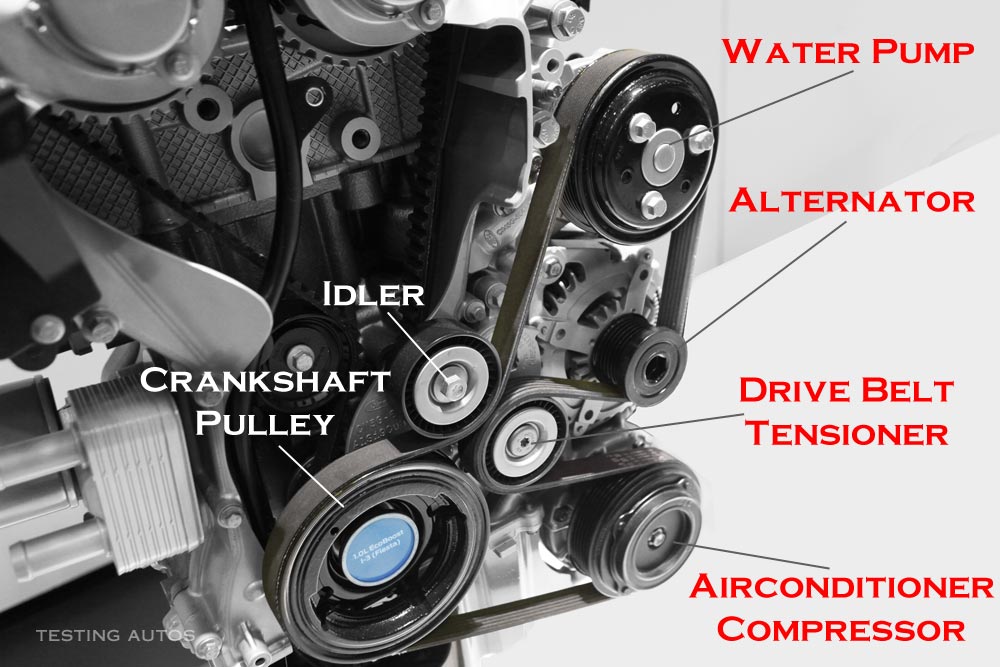

Older vehicles use v-belts which typically only drive the AC compressor. Modern vehicles use serpentine belts to drive all of the engine accessories including the drive belt. Over time belts crack and deteriorate.

Replacing the belt at the first sign of wear ensures it wont break leaving you without AC. Remove the belt once you have enough play between the pulleys. Place the new belt on and slide the belt tensioner backwards so that the new belt is completely taut.

Tighten the belt tensioner bolt with your socket set. Increase the tension on the belt. If your vehicle does not have an auto tensioner insert a pry bar or piece of wood between the alternator and the engine.

Run the belt over the alternator pulley then use the bar to pry the alternator away from the engine and increase the tension on the belt. Tighten the bolts again as you apply tension. Locate the adjustment fastener and loosen it.

This is usually on the alternator mounting or on a separate pulley wheel. Move the adjusting mechanism in far enough to allow you to remove the belt. Some vehicles use an automatic spring tension system.

In that case pull the tensioning device back so that you can remove the belt. Belt Installation Step 1. Install the new serpentine belt clockwise around the alternator pulley fan pulley and crankshaft pulley.

Pull the alternator assembly away from the center of the engine block. This will create tension in the. Hold the alternator in place keeping tension.

If your car or trucks serpentine belt fan belt or alternator belt is worn now is the time to replace it with these step-by-step instructions. Entertainment Music TV Film Performing Arts Visual Arts Fashion Style Love Romance Gaming Hobbies Fine Arts Crafts. Learn how to fix a squeaky tensioner pulley in your car.

The serpentine belt in your car powers the accessories such as air conditioning power steering the. The replacement cost of an alternator belt is typically between 100 and 200. The part cost is between 25 and 80 while the labor cost is between 75 and 120.

The true replacement cost will depend on how long it takes the mechanic to access your alternator belt. Sometimes it is easy to access so the labor will only take one hour or so. Multi-Grooved Or Ribbed V Belts.

Purchasing Replacement Accessory Belts. Look up fan belt in any modern automotive dictionary and youll typically find a definition that reads An endless belt used to transmit power from a crankshaft-driven pulley to a pulley driving the fan alternator or other engine accessory. How to replace a fan belt on a 6400 john deere tractor.

Sometimes things that you think will be really complicated end up being easy to fix. The Heavy Equipment Mechanic Im going to connect you with knows all the tricks and shortcuts. Fan belt replacement 6400 john deere.

How to Quiet a Noisy Fan Belt Method 1of 3. Applying Belt Dressing to Neoprene Belts. Ensure your vehicle is equipped with a neoprene belt.

Tightening or Aligning a Fan Belt. Inspect the belt for misalignment. A common cause of noisy fan belts.