The first is that the component detects and prevents engine damagespecifically preignition and detonation due to damage of the pistons rods valves gaskets and plugs. Its a piezoelectric automotive sensor that produces a small voltage signal when it hears internal engine noise that we often call knock and ping.

Knock sensors also.

Purpose of knock sensor. Bad knock sensor symptoms. A failed knock sensor will register a trouble code and illuminate the Check Engine lamp CEL although some engines will require multiple failure. Vibration especially at highway speed.

Thumping or knocking noise from the engine. Poor fuel economy and. The knock sensor serves a handful of critical purposes for your car.

The first is that the component detects and prevents engine damagespecifically preignition and detonation due to damage of the pistons rods valves gaskets and plugs. The sensor is able to detect knocking and pinging noises that are imperceptible to the drivers ear. Signs of a Bad Knock Sensor.

Loss in Engine Performance. The PCM uses the data sent by the knock sensor to change the ignition timing which can have a direct effect on. Check Engine Light Illuminates.

Spark Plugs Go Bad. A knock sensor is essentially a small listening device in or on the engine that detects these irregular vibrations and sounds that come from the engine block. The knock sensor picks up vibration.

What Is a Knock Sensor. A knock sensor is a knob-like part that is linked to the cars engine. As the name implies it senses.

One of the purposes of a knock sensor is to monitor the performance of the engine. If there is a problem. Knock sensors also.

The purpose of the knock sensor is to sense unusual pulsations caused by the engine detonation. It is basically the computers ear to the engine to determine if it is working properly. To get a better understanding of how a faulty knock sensor reacts note the points below.

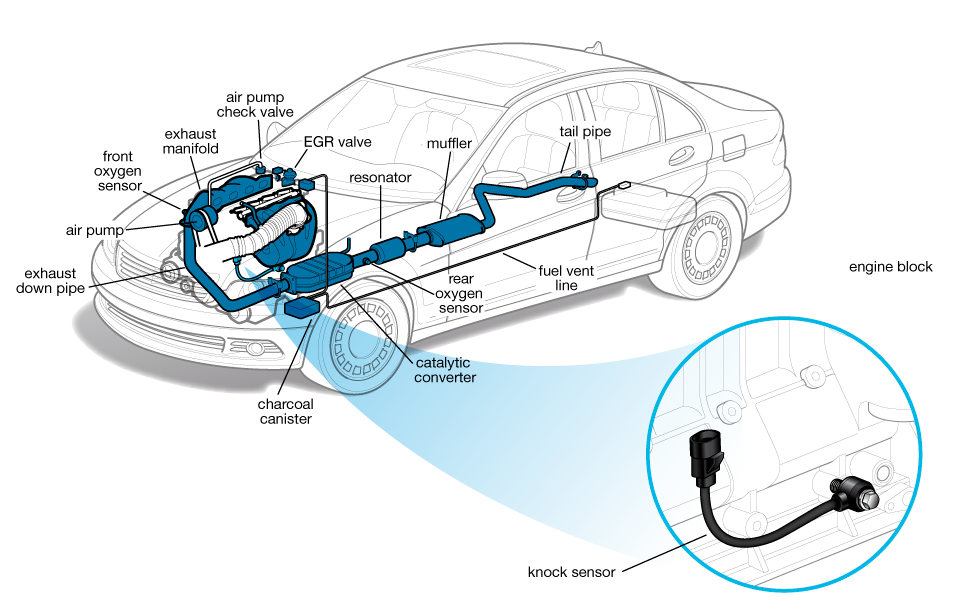

The knock sensor is located on the engine block cylinder head or intake manifold. Its senses vibrations caused by engine knock or detonation. The PCM uses this signal to alter the ignition timing and prevent detonation.

It compares this information with its preset tables to identify a valid knock or ping. Located in the lower engine block cylinder head or intake manifold the Knock Sensors are made to create the voltage signal based on the vibrations that are caused by the detonation. The sensors basically cause the voltage signal based on the vibrations that detonation causes.

The purpose of the knock sensor is to sense unusual pulsations caused by the engine detonation. It is basically the computers ear to the engine to determine if it is working properly. An engine knock sensor is designed to detect these unplanned explosions and send a voltage signal to the ECU or powertrain control module.

From there the module will delay the ignitions timing and prevent engine detonation. Retarding delaying the ignition timing means the spark plugs fire a bit later than they used to. The knock sensor is one kind of sensor used to detect the flash knock.

This flash is the state within the engine of the automobile where the fuel starts burning because of the pre-ignition detonation otherwise pinging. The main function of this sensor is to monitor the ignition process inside the engine. The purpose of the knock sensor is to sense unusual pulsations caused by the engine detonation.

The computer in the vehicles control system can detect the different sounds in the cars engine. The computer in the vehicles control system can detect the different sounds in the cars engine. The purpose of the engine knock sensor is to diagnose unusual pulsations and abnormal combustion caused by the engine detonation too early or too late.

This is basically in charge of the computer of the car and the ears of the car determining if the engine is working correctly. One sensor in particular called the knock sensor acts as a sophisticated listening device in the engine. It detects any engine noises caused by detonation – when fuel explodes in an engines cylinder– and adjusts ignition timing accordingly.

To me the most interesting part about the knock sensor is that it only has one wire going to it. The reason for this is the sensor generates its own voltage and is case grounded. Its a piezoelectric automotive sensor that produces a small voltage signal when it hears internal engine noise that we often call knock and ping.

Knock sensors are solely used for the purpose of sensing when your engine is knocking or sensing when there is exploding in the airfuel mixture in a way that delivers less power and can also damage the engine if prolonged. When the engine knocks there is an excessive amount of NOx that is released. The main purpose of the knock sensor is to monitor the performance of the engine.

It is a sensor that is screwed into the engines block or cylinder head. The knock sensor sends signals to the Powertrain Control Module PCM to control the engines timing.