You can accomplish this with the end of a dial caliper the depth gauge portion at the back of the scale but its far easier and more convenient to use a commercial ring-squaring tool Summit Racing has more than 30. Maximum ring gap is an important part of ring performance in that too much gap results in lost compression power loss and ultimately poor oil control.

Check out Kalvinator Engines.

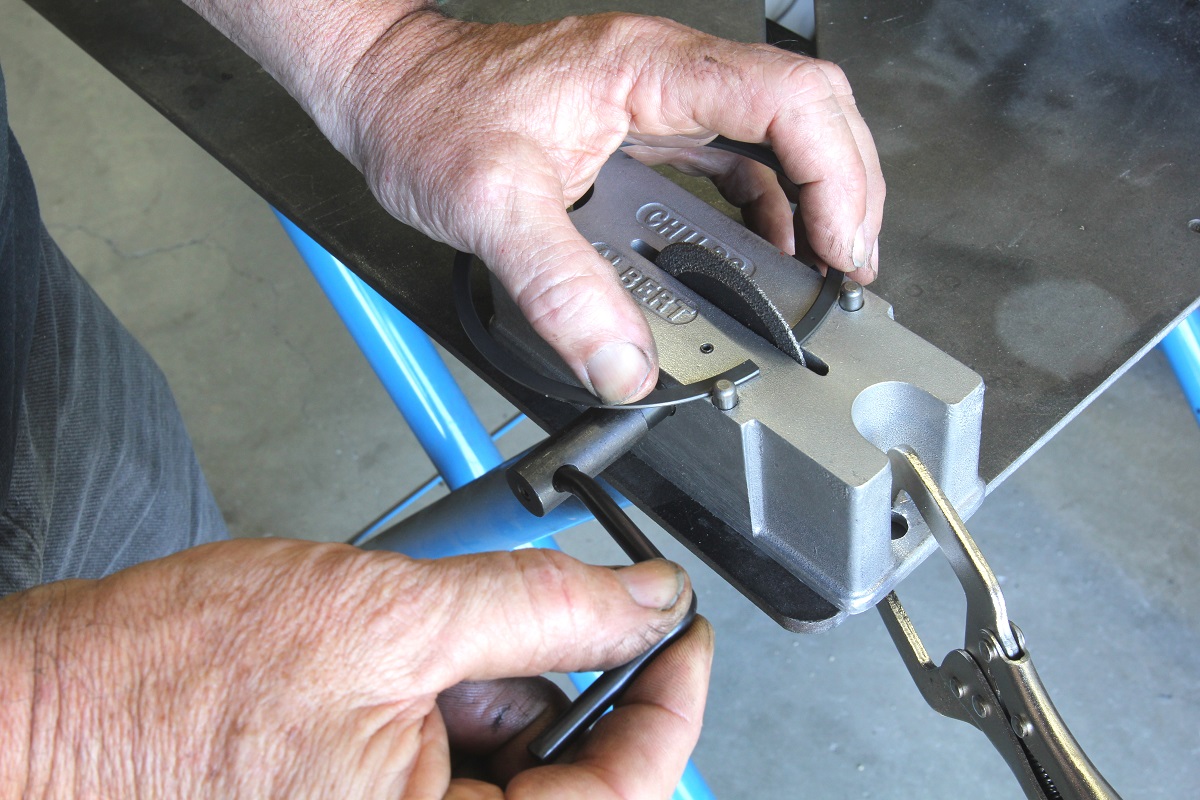

Piston ring gapping tool. Set ring end gap with this exclusive filer Features carbide grinding wheel for extended life Cuts chrome plated or stainless steel piston rings quickly and accurately Can be mounted to any work bench Disc measures 2283 OD. And is 080 thick See more product details. The right gap size can vary by ring material bore size piston material and application but the right tool for grinding rings down to the proper size is a piston ring filer.

Weekend mechanics can usually get by with a manual crank filer but professional engine builders may need the speed and repeatable accuracy of an electric filer. We have the best Piston Ring Tool for the right price. Buy online for free next day delivery or same day pickup at a store near you.

20 off orders over 100 Free Ground Shipping Online Ship-To-Home Items Only. 20 off orders over 100 Free Ground Shipping. This tool is designed to be a guide.

We always recommend consulting specific manufacturers instructions on piston ring gaps. To gap your piston rings you will need these tools. For help with how to file your piston rings please see our Piston ring gapping and filing guide.

You can purchase a ring-squaring tool like this one or you make your own by placing a second ring on an old slightly smaller flat-top piston. The flat top of the piston will square the ring in the bore and the best part is this tool costs nothing. Piston Ring Squaring Tool Billet Aluminum Adjustable from 375 in.

Automotive Engine Piston Ring Compressor Tool SetKIOIPOSet with Pliers and 14 BandsCar Engine Piston Ring Compressor Pliers Set for Car Truck Auto Engine with Pliers 41 out of 5 stars 20 2629 26. Use a ring squaring tool to seat the piston ring squarely in the bore and a feeler gauge to check its gap. Check the gap often and grind slowly to prevent ruining the ring.

When filing the rings sneak up on the final gap. Go slowly removing minimal material at a time and re-checking the gap often. A feeler gauge inserted into the ring gap will show you the existing dimension and from there you can make your adjustments.

For a street engine multiplying your bore size by 0004in will give you the top ring gap you are looking for. 004 x 400in bore 0016 inch ring gap. HOMEMADE PISTON RING GAPPING.

Use of this tool will prevent damage of your finished bore. Piston ring end gap gauges are available in any bore size. They are accurately machined with an internal step to square the ring and have a relief cut for the feeler gauge.

This tool can make quick work of a tedious job. This video covers how to check piston ring gap using a feeler gauge or feeler gauge set along with a piston ring squaring tool. Keep in mind ring gap recommendations will vary based on bore size expected engine pressures and heat.

Things like intended use street or race and engine setup naturally aspirated versus forced induction will play a part. Do not assume the rings have been pre-gapped or begin the ring gapping process without reading the recommendations from the manufacturer. Maximum ring gap is an important part of ring performance in that too much gap results in lost compression power loss and ultimately poor oil control.

The following chart indicates the specifications for compression ring gap as outlined by the Society of Automotive Engineers SAE as standards for the automotive piston ring manufacturers. Use the piston to square up the ring in the bore and check the end gap by using a feeler gage. See table below for proper ring end gap for your application.

The oil rails may be installed without modifying the end gap. The gap should be a minimum of 010. Ring Gap Table Instructions 1.

This table is in inches. Now we need to file the rings this is a bench mountable piston ring filing tool. When filing the rings it is important to keep the filed edge square.

This actually means taking some off both sides of the gap. When the gap is pushed together and closed the two side should met up perfectly. Check out Kalvinator Engines.

Especially if its a performance. The ring must be squared in the bore. You can accomplish this with the end of a dial caliper the depth gauge portion at the back of the scale but its far easier and more convenient to use a commercial ring-squaring tool Summit Racing has more than 30.

In this case the ring is inserted in the bore followed by the squaring tool. To accurately measure piston end gap you will need a piston squaring tool to accurately place the ring in the bore. This particular tool left is similar to the ProForm tools that offers double sided steps for a wider range of use.

Featured are MAHLE Motorsports tech videos and instructional videos that offer an in-depth discussion into the latest in piston technology. The Compression Ratio Calculator and 2020 Ring End Gap Instruction Information is also available for download.